Researchers at Virginia Tech have utilized the ancient Japanese art of Kirigami, paper cutting, to enhance the strength of sticky tape while also making it easier to remove compared to existing super-adhesives.

Whether you need to swiftly fix household items or ensure a secure package seal for mailing, having tape with a strong bond is essential. However, the drawback of conventional super-adhesives is the challenging removal process, often requiring scraping and hoping that the surface remains intact.

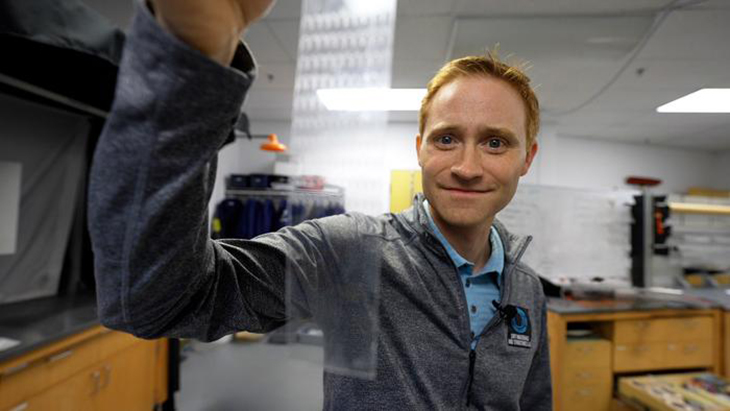

Professor Michael Bartlett and his team at the university have achieved a significant breakthrough by substantially boosting the adhesive bond of the tape while ensuring its easy removability.

“This seemingly paradoxical combination of properties could dramatically change applications in robotic grasping, wearables for health monitoring, and manufacturing for assembly and recycling,” Prof. Bartlett had explained.

In the 1920s, a revolutionary concept took shape with the creation of easily removable masking tape. Initially devised to cater to the demands of car painters seeking improved techniques for applying two colors on vehicles, this innovation has since paved the way for a multitude of practical applications.

Over the years, manufacturing facilities have introduced various types of tape to suit diverse needs. Among these innovations, invisible tape gained popularity as an ideal solution for elegantly wrapping presents, while electrical tape emerged as a reliable choice for safeguarding wires. Notably, duct tape, originally designed for specific purposes, has transcended its intended use, finding its way into countless applications beyond its initial scope.

“Normally, when tapes are peeled off, they separate in a straight line along the length of the strip until the tape is completely removed. Strong adhesives are made more difficult to peel, while reusable adhesives promote the strength-limiting separation.”

Bartlett’s approach involved harnessing the concept of “separation path,” drawing inspiration from kirigami techniques that employ folding and cutting to convert flat paper sheets, similar to the way kids create paper snowflakes. By making a sequence of U-shaped incisions on an adhesive material, they made a fascinating discovery: these cuts remarkably enhanced the tape’s bonding strength by an impressive factor of 60.

“An engineered cut can force the adhesive separation path to go backwards at specific locations, which we call reverse crack propagation, making the adhesive very strong. But by peeling in the opposite direction, it always goes forward, making it easy to remove.”

“This is quite unusual behavior, but it is very useful to make strong yet releasable adhesives.”

The team made a noteworthy discovery, which was published in Nature Materials, stating that the specific type of tape used didn’t make a difference. The application of Kirigami consistently enhanced the bonding properties of various tapes, ranging from packaging tapes to medical tapes. In each case, the already strong adhesive bonds became even stronger, and even the typically weaker adhesives exhibited increased strength as well.

“What really matters is the shape and size of the cut,” said former graduate researcher Dohgyu Hwang.

“We do not have to rely on the specific adhesive material, but as long as the cuts are made at a characteristic size, which is defined by the physics of the adhesive, we found that this enhanced adhesion in every system we tried.”

“We also use a rapid digital fabrication approach, so we can quickly create highly customizable adhesives with tunable strength,” said Bartlett. “This is very exciting for the development of future adhesives.”

What are your thoughts? Please comment below and share this news!

True Activist / Report a typo