Materials thrown to dump sites remain there for years. Some can emit dangerous chemicals that pose health risks. There needs to be a way to dispose of these materials safely and efficiently, and this is what environmentalists have been thinking about for years.

As for the trash themselves, there are many out there that can be recycled to make new materials. Then, there are some that can simply be fixed and revived. It’s all a matter of planning so that you know what to do with the accumulated waste.

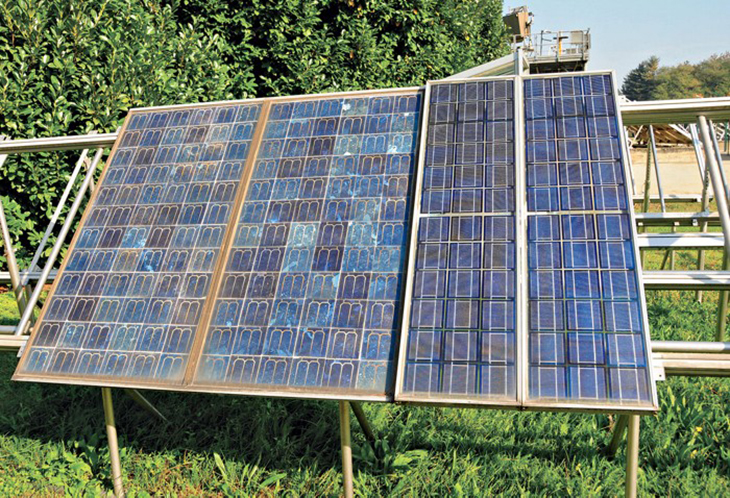

An American company called Solar Cycle has taken on the task of transforming broken solar panels from landfill waste to raw materials that are crucial to making more solar panels. This is perfect because there is now a trend of transition to renewable energy. This is how we can make a planet more green, and during this change, there is an unprecedented need of solar panels and batteries in large volumes.

Solar Cycle knows that in order to make this transition possible, a circular economy is needed wherein key materials and components present can be used and reused. The faster we can make the change, the better the climate will be because companies won’t need to turn to mining companies that only destroy nature’s raw materials.

Materials such as copper, aluminum, silver, and silicon are all recovered from panels once they reach the end lifecycle, and with the company’s new recycling practices, they are able to reduce all these to just 2 percent of their original weight.

A report by the International Renewable Energy Agency in 2016. They saw that by the mid 2030s, it is highly possible that millions of metric tons of solar panels will be decommissioned. If no one would be able to think of a way to economically recycle them, they would simply be thrown into a landfill and left to rot for decades.

While the situation may seem dire, a group of Australian scientists found a method of electrostatically separating waste streams that come from solar panels. These are fed into large machine-grade shredders after the aluminum frame is removed. Then, the solar cells that they get are shredded. The new method reaps profits and is beneficial, especially when it comes to shredding the small amounts of solar arrays.

The process they came up with is able to can chew up around 220,000 pounds (1,000 tons) of solar panels per year. This is somewhat equivalent to 50,000 panels, said lead author Dr. Pablo Dias.

“This is something someone can pick up elsewhere, it doesn’t use any chemicals, it doesn’t emit any hazardous pollution. It produces dust from crushing the panels, but you have dust collectors there,” Dias told the Guardian.

Dias has recently gone to work to apply his technology and he did this as a representative of Solar Cycle. With the project made, he was able to attract investment from businesses involved in the solar market such as Sun Power, Solar City, and Closed Loop Partners, and that was because they saw the benefits that came with it.

“For solar to truly scale to its full potential, we need to create renewable supply chains and a vibrant secondary market for used panels and recycled materials,” Solar Cycle states.

Right now, Solar Cycle is the only dedicated technology-based recycling company in the industry, and they recently closed a deal for end-of-life solar array recycling together with their first utility-scale partner, Silicon Ranch, a company that operates a total of 145 solar power facilities all over the U.S.

What are your thoughts? Please comment below and share this news!

True Activist / Report a typo