An Australian company has managed to create a completely new electrolyzer in order to broaden the use of hydrogen fuel. They also share that this depicts the first ‘real revolution’ in this type of technology over the last 200 years.

“Electrolysis” is the process of separating water into hydrogen gas and oxygen through electrical current, and it happens to be the main method behind green hydrogen energy, while also being highly expensive and inefficient.

But hydrogen could become the only choice available when it comes to wanting to go green and be sustainable in replacing petroleum for long-haul trucking, steel manufacturing and more. Swedish company SSAB Is already trying to do their part by making steel eco-friendly by using hydrogen to replace coal as a carbon input, creating “green steel.”

Hysata, the Australian firm, even made changes to the design of the major component to find a way to make the cost of pure hydrogen fuel competitive with fossil fuels. They did this by decreasing the heat and resistance that usually occurs during the process of separating hydrogen.

Hysata’s chief technology officer and a professor at the Univ. of Wollongong, New South Wales, Gerry Swiegers, to the publication The Guardian, “What we did differently was just to start completely over and to think about it from a very high level. Everyone else was looking at improving materials or an existing design.”

A scientific paper, which was published in Nature, demonstrated their new electroylyzer’s potential. First, they outlined the problem with the old ones, which was showing that ‘even state-of-the-art water electrolyzers typically require at least 53 kilowatt-hours of electricity to produce 1 kg of hydrogen, which contains 39.4 kWh of energy: a deficit of 12.’

Trouble In the Bubble

But before we can truly understand why that deficit exists, it’s important to understand how these devices work in the first place.

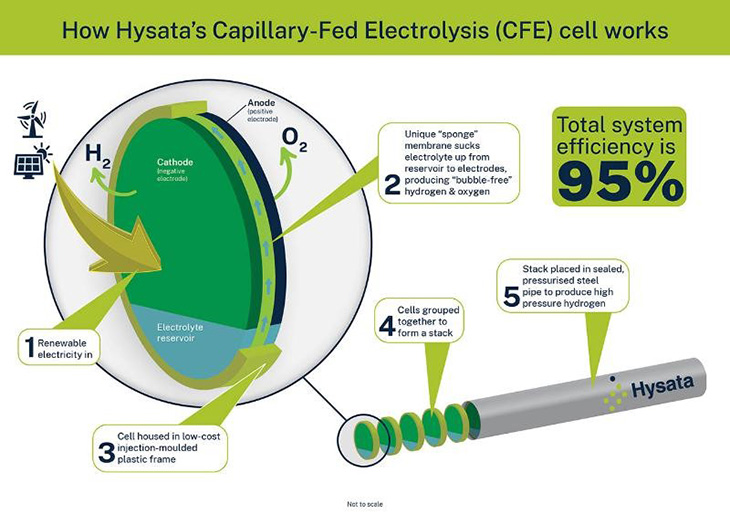

Simply explained by the Fuel Cell & Hydrogen Energy Assocation, an electrolyzer consists of ‘an anode and a cathode separated by a sponge-like membrane. H20 is sent into the anode, where its electrons are stripped and turned into electricity, powering whatever it’s connected to. Its positively charged protons then cross through the membrane into the cathode, where oxygen is pulled into. There, the protons, reunited with their electrons post-electricity harvest, combine with the oxygen to form water and heat: the only emissions.’

When it comes to Hysata, they are making a big change from their former traditions through their electrolyzer’s circular shape. The hydrophilic membrane sits in just a bit of an electrolyte reservoir in the same place where the water enters. Then the membrane ‘continuously pulls up the water and the electrolyte in steady amounts that allow electrolysis to occur without the formation of hydrogen gas bubbles’ that are very typical of electrolyzers that usually house the anode and cathode completely within the hydrogen reservoir.

These gas bubbles then block the physical access to the catalyst on the anode and cathode, with reduces their efficiency. Moreover, the elimination of the gas bubble problem ends in Hysata’s success rate of 95%, or roughly 41.5 kWh per kilogram of hydrogen.

In addition, Hysata isn’t just about the science. The economics of their electrolyzer also make sense since the membranes are not only easy to manufacture, but the process can also be automated at scale, they share.

The International Renewables Energy Agency has set a 2050 target to invent new and innovative ways of electrolysis that will lessen the kWh required per kilogram that’s produced at 42. Hysata is currently the only company anywhere that has achieved that.

One example of this is if a long-haul trucking sector needed 1 million tons of hydrogen annually, producing that with the technology of Hysata could save up to $3 billion. Now that’s impressive.

What are your thoughts? Please comment below and share this news!

True Activist / Report a typo