Researchers have achieved an impressive breakthrough in their pursuit of enhancing the strength and lightness of materials by combining the seemingly disparate elements of DNA and glass. This novel approach has the potential to revolutionize diverse industries, spanning transportation to healthcare.

According to Seok-Woo Lee of the University of Connecticut (UCONN), who partnered with colleagues from Columbia University and Brookhaven National Lab, said, “For the given density, our material is the strongest known.”

“I am a big fan of Iron Man movies. I have always wondered how to create a better armor for Iron Man. It must be very light for him to fly faster. It must be very strong to protect him from enemies’ attacks,” shared nanomaterials scientist Oleg Gang.

“Our new material is five times lighter but four times stronger than steel,” he added.

Traditionally, metals like titanium have been lauded for their remarkable strength-to-weight ratio, far surpassing that of iron. The advent of specialized alloys has further propelled this concept, enabling the creation of lightweight body armor, advanced medical equipment, and faster, safer automobiles and aircraft. Nevertheless, the field of metallurgy appeared to have hit a plateau, catalyzing the exploration of nanomaterials as an exciting avenue for innovation.

In a recent publication within Cell Reports Physical Science, a consortium of scientists introduced in incredibly robust yet lightweight material crafted from DNA and glass. While the selection of glass may seem unconventional, it was motivated by its intrinsic characteristics and the imaginative thinking of the research team.

Glass’s susceptibility to shattering is typically attributed to structural imperfections, such as cracks, abrasions, or missing atoms. In contrast, an unblemished cubic centimeter of glass can withstand substantial pressure, enduring loads exceeding ten tons – more than three times the pressure that caused the Oceangate Titan submersible to implode near the Titanic.

As per UCONN News, the primary challenge lies in producing large, flaw-free glass components, a feat the researchers tackled by working with nano-sized glass pieces, usually less than a micrometer thick and nearly always free of detects. Furthermore, the lower density of glass in comparison to metals and ceramics made it a compelling candidate for constructing lightweight, strong structures.

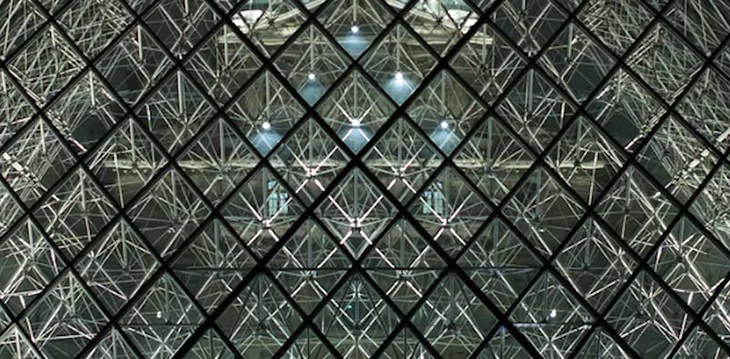

The research team embarked on this groundbreaking endeavor by fabricating a self-assembling DNA structure, akin to interlocking building blocks that snapped together to create a scaffold-like framework. This DNA scaffold, reminiscent of the skeleton of a building, formed the basis for their groundbreaking material.

Adding another layer of complexity, Gang and Aaron Mickelson, affiliated with Columbia and Brookhaven’s Center for Functional Nanomaterials, coated the DNA structure with an incredibly thin layer of a glass-like material, often only a few hundred atoms thick. This innovative approach conserved significant void spaces within the material, mirroring the rooms within a building.

Crucially, the DNA scaffold, akin to scaffolding in construction, fortified the fragile glass coating, rendering the material incredibly sturdy while maintaining its lightness. The voids, occupying a substantial proportion of the materials’ volume, contributed to its overall lightweight nature.

“The ability to create designed 3D framework nanomaterials using DNA and mineralize them opens enormous opportunities for engineering mechanical properties.” Gang explained in a UConn News release.

The result was a glass nanolattice structure, a material that successfully merged with unparalleled strength the exceptional lightness. Nevertheless, the journey of research is far from over. The team is presently exploring the substitution of even more robust carbide ceramics for glass while preserving the same DNA framework.

This marks the inception of an auspicious era in materials science, with the researchers intending to investigate various DNA structures to identify the ones that produce the strongest material.

Dr. Lee, a pivotal figure in this innovative research, envisions the DNA origami nanoarchitecture as a pioneering avenue for fabricating materials that are lighter and more robust than anything previously conceivable. The ramifications of this development are profound, potentially reshaping various industries such as aerospace, automotive, and medical technology. Strong, lightweight materials constitute the cornerstone of groundbreaking advancements, offering the potential for more efficient transportation, safer medical devices, and countless other yet-to-be-discovered applications.

The future may very well hinge on the seemingly improbable fusion of DNA and glass, unlocking uncharted realms in material engineering that hold the promise of a brighter and more efficient future.

What are your thoughts? Please comment below and share this news!

True Activist / Report a typo