Hundreds of years ago, alchemists believed that they would be able to turn lead into gold. And today, the idea of generating valuable materials from majorly abundant resources is also what leads scientists in their continued pursuit of golden opportunities.

In fact, the U.S. Department of Energy’s Pacific Northwest National Laboratory (PNNL) is working hand in hand with other companies in order to test the possibility of using magnetic nanoparticles to capture critical materials, like lithium, from a variety of wastewater sources.

Currently, lithium has become one of the most essential ingredients in a number of energy and electronic technologies, which includes the lightweight lithium-ion batteries that power everything these days, from smartphones to tablets to electric vehicles.

This also means that the global market for lithium is monstrous, yet only very little lithium happens to be produced within the United States.

Currently, there is a patent-pending technology that is being developed in a lab in Richland, Washington, which can provide the opportunity to produce not just lithium, but other critical materials as well. It will also do the job at a lower cost, while being quicker as well.

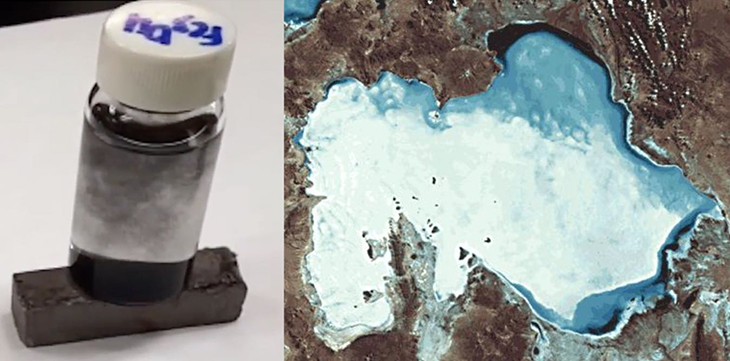

The main function of this process are the magnetic nanoparticles that are surrounded by an absorbent shell which latch onto the lithium and other types of material that are found in water and used in a variety of industrial processes. This includes water that’s used in geothermal power plants – also known as geothermal brines – or the water that’s pulled out from the subsurface during the production of oil and gas.

Moreover, lithium is present in most of the water that gets pumped during the gas and oil extractions across the United States and Canada. The PNNL scientists also estimate that ‘if just 25 percent of the lithium in such water were collected today, it would equal the current annual worldwide production.’

There is ongoing testing, which involves PNNL, Conoco Phillips, Moselle Technologies, and Natural Resources Canada. According to PNNL, the team is also stress-testing the technology by “subjecting it to extended cycle testing with the magnetic separator system, a needed step for full-scale industrial production.”

CEO of Texas company Moselle, Jerry Mills, which has licensed the technology and hopes to pilot it in a number of locations said, “By using the magnetic nanoparticles to attach to the lithium particles in solution, we expect the resulting concentrate to be in a purer form, thereby reducing the cost of further processing, and this will take out more than half the cost.”

When the tiny, iron-based particles are added to the water, the lithium is pulled out of the water and binds to them. After which, using the help of a magnet, the nanoparticles can then be collected in just a few minutes with the lithium going along for the ride, no longer being suspended in the liquid but rather quite ready for easy extraction.

Even better, once the lithium is extracted completely, the recharged nanoparticles can be used once more. The process could also be used in effluents from desalination plants, or even taken directly from seawater supposedly.

In addition, the PNNL process goes to work right away. As compared to the conventional lithium extraction techniques that work usually by pumping groundwater into big and expensive evaporating ponds – many of which take months or even years to evaporate enough to even access the lithium – while also impacting groundwater management in dry regions where they are usually placed, such as Australia, China, and Chile.

Could Cause a Geothermal Boost and More

Should this technology be deployed at geothermal plants, it’s believed that that value of the lithium that’s recovered could possibly increase the cost-effectiveness of this type of clean renewable energy, which ‘uses water to capture the heat deep below the earth’s surface and then converts it into green electricity.’

Aside from Moselle, they are also joining forces with other commercial partners to study the use of this technology for their lithium resources in both Nevada and Canada.

Moreover, looking at different types of applications, the researchers at PNNL are looking to customize the shell of the nanoparticle to specifically target other commercially valuable elements and minerals that are used in everyday energy technologies, such as medical imaging devices, and more.

One example of this is their collaboration with Moselle and Geo40 to look into the possibility of extracting cesium and antimony from geothermal brines at the geothermal plant located in New Zealand.

Director of Pacific Northwest National Laboratory (PNNL), Steven Ashby, said, “PNNL’s novel approach is truly remarkable. It offers the promise of extracting critical minerals in a quick, cost-effective manner. And innovation like this just might be worth its weight in gold.”

What are your thoughts? Please comment below and share this news!

True Activist / Report a typo