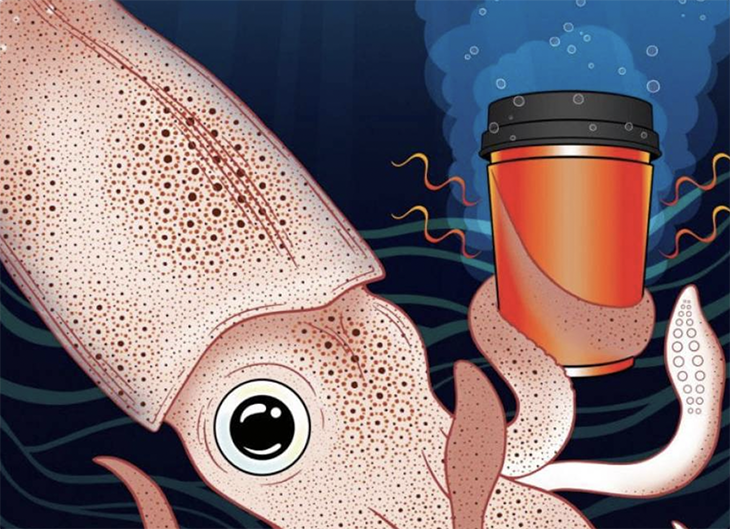

Strange as it sounds, but a group of innovative scientists have made a coffee cup that is meant to keep your coffee hot on even the coldest of days.

Engineers from the University of California in Irvine got their inspiration for the coffee cup from the skin of a cephalopod, which is an animal grouping where squid and octopus belong. The engineers created an adaptive composite material that has the ability to insulate beverage cups, parcel boxes, restaurant to-go bags, as well as shipping containers.

This amazing infrared-reflecting metallized polymer film was produced in the laboratory of Alon Gorodetsky, who happens to be a UCI associate professor of chemical and biomolecular engineering. He and his team explain that the large-area composite material has the ability to regulate heat through reconfigurable metal structures which can ‘reversibly separate from one another and come back together under different strain levels.’

According to lead author and former UCI postdoctoral scholar in chemical and biomolecular engineering, Mohsin Badshah, he shares that it’s also good for the environment since it’s considered sustainable. He says, “The composite material can be recycled in bulk by removing the copper with vinegar and using established commercial methods to repurpose the remaining stretchable polymer.”

Gorodetsky shares, “The metal islands in our composite material are next to one another when the material is relaxed and become separated when the material is stretched, allowing for control of the reflection and transmission of infrared light or heat dissipation. The mechanism is analogous to chromatophore expansion and contraction in a squid’s skin, which alters the reflection and transmission of visible light.”

Gorodetsky explains that it’s the chromatophore size that helps squid communicate and camouflage their bodies in order to hide and evade prey that’s chasing after them. He says that by mimicking this same approach, his research team managed to enable the “tunable thermoregulation” within the material they produced, which in turn can ‘lead to improved energy efficiency and protect sensitive fingers from hot surfaces.’

Moreover, they also explain that one of the main breakthroughs of the project was the UCI researchers’ development of ‘a cost-effective production method of their composite material at application-relevant quantities.’ According to their paper, the raw materials used – copper and rubber – normally begin at just a dime per square meter, reducing the costs further in economies of scale.

The research team uses a fabrication technique that involves depositing a copper film onto a reusable substrate such as aluminum foil, after which they spray multiple polymer layers onto the copper film. Incredibly, this can also be done in almost any batch size too.

Gorodetsky says, “The combined manufacturing strategy that we have now perfected in our lab is a real game changer. We have been working with cephalopod-inspired adaptive materials and systems for years but previously have only been able to fabricate them over relatively small areas. Now there is finally a path to making this stuff roll-by-roll in a factory.”

In addition, the developed strategy and economies of scale may just make it possible to use the composite material in a wide variety of items, such as tents, coffee cup cozies, or even containers where variable temperature regulation is required.

To test their material, the research team conducted coffee cup testing in their laboratory on the UCI campus. Here they were able to prove that they could actually control the cooling of the coffee. Using the cups, they managed to accurately and theoretically predict the changes in temperature of the liquid inside the cups. They were even able to achieve a ‘20-fold modulation of infrared radiation transmittance and a 30-fold regulation of thermal fluxes under standardized testing conditions.’ And despite high levels of mechanical deformation and even repeated mechanical cycling, the material remained stable.

“There is an enormous array of applications for this material. Think of all the perishable goods that have been delivered to people’s homes during the pandemic. Any package that Amazon or another company sends that needs to be temperature-controlled can use a lining made from our squid-inspired adaptive composite material. Now that we can make large sheets of it at a time, we have something that can benefit many aspects of our lives,” explains Gorodetsky.

If you’d like to see the study results, they are published in the journal Nature Sustainability.

What are your thoughts? Please comment below and share this news!

True Activist / Report a typo